Choosing the right print bed is crucial for a successful 3D printing experience. The print bed is where your 3D prints take shape, and its type can significantly affect print quality, adhesion, and ease of removal. Here’s a quick guide to the different types of 3D printer beds, including materials, heated vs. non-heated options, and their pros and cons.

1. Glass Beds

- Material: Borosilicate glass is commonly used for its heat resistance and flatness.

- Heated vs. Non-Heated: Usually paired with a heated bed.

- Pros: Smooth surface that provides a glossy bottom finish, excellent for PLA, ABS, and PETG. Easy to clean and resistant to warping.

- Cons: Poor adhesion without adhesives (like glue stick or hairspray), especially with certain filaments.

2. Aluminum Beds

- Material: Typically made from aluminum or aluminum alloy.

- Heated vs. Non-Heated: Often heated to improve adhesion.

- Pros: Good heat distribution, sturdy, and less prone to warping. Ideal for printing ABS and other filaments that require consistent heat.

- Cons: Surface can scratch easily; requires a surface covering like PEI, tape, or build sheets to enhance adhesion.

3. PEI Sheets (Polyetherimide)

- Material: A thin, durable plastic film applied to a metal or glass bed.

- Heated vs. Non-Heated: Best with heated beds for optimal adhesion.

- Pros: Excellent adhesion with a wide range of filaments, including PLA, ABS, and TPU, often without additional adhesives. Prints release easily when cooled.

- Cons: Can wear over time; replacing or maintaining the sheet can be necessary.

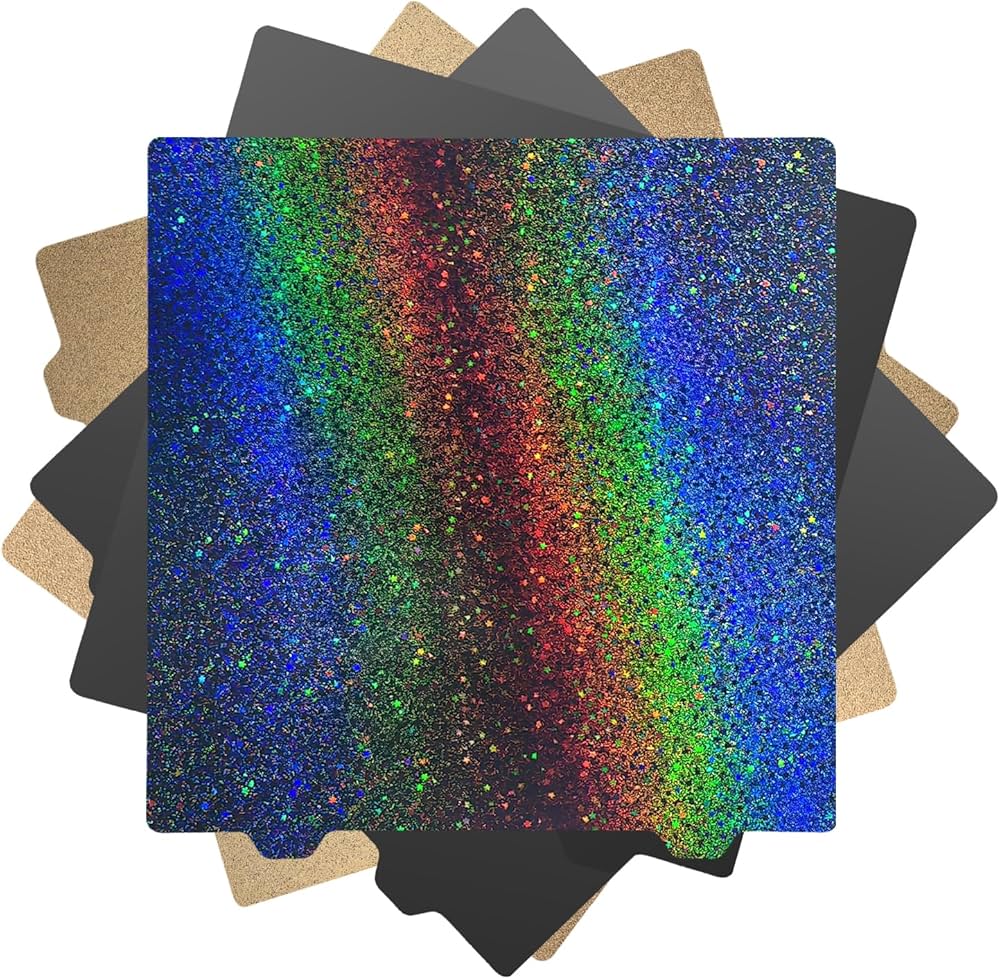

4. Magnetic Flex Beds

- Material: A spring steel sheet covered with a print surface (like PEI) on top of a magnetic base.

- Heated vs. Non-Heated: Commonly used with heated beds.

- Pros: Easy print removal by flexing the sheet; strong adhesion while printing. Works well with most filaments.

- Cons: Magnetic adhesion can weaken over time; heat may affect magnet strength slightly.

5. BuildTak and Similar Surfaces

- Material: Proprietary plastic surfaces that can be adhered to glass or aluminum beds.

- Heated vs. Non-Heated: Typically paired with heated beds.

- Pros: Good adhesion with multiple materials, durable, and easy to apply. Compatible with most filaments.

- Cons: Can be hard to remove prints if over-adhered; the surface can be damaged by sharp tools.

6. Textured Glass Beds

- Material: Tempered glass with a textured surface.

- Heated vs. Non-Heated: Usually heated to improve filament adhesion.

- Pros: Great adhesion without adhesives for filaments like PLA and PETG; easy print removal when cooled.

- Cons: Not as effective with certain filaments like ABS without additional adhesives; can be prone to chips if prints are forcibly removed.

Heated vs. Non-Heated Beds

- Heated Beds: Improve adhesion and reduce warping, especially for high-temperature filaments like ABS and PETG. They help maintain consistent temperatures during printing, which is crucial for minimizing print defects.

- Non-Heated Beds: Suitable for low-temperature filaments like PLA. They are simpler to set up and cheaper but may struggle with warping and adhesion issues, requiring adhesives like blue painter’s tape or glue.

Conclusion

The choice of print bed depends on your specific 3D printing needs, including the types of filaments you use and the level of convenience you desire. Understanding the differences between bed materials and the benefits of heated versus non-heated beds will help you achieve the best results in your 3D printing journey.