Choosing between direct drive and Bowden extruders is one of the key decisions when setting up a 3D printer, and each option has its own strengths and weaknesses. Understanding these differences can help you make the best choice based on your printing needs.

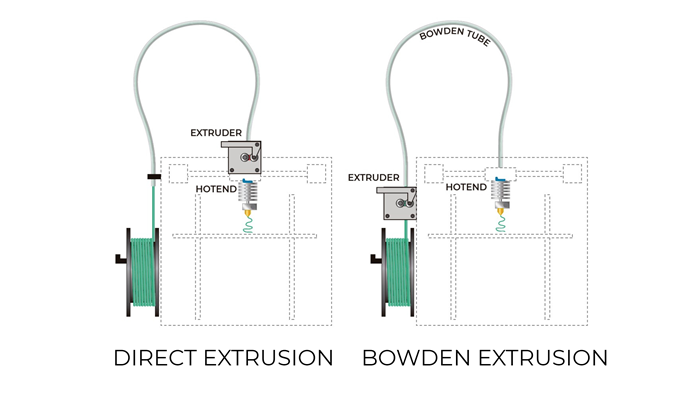

1. Position and Mechanism

- Direct Drive Extruders: In a direct drive setup, the extruder motor is mounted directly on the print head. This means the filament is pulled directly into the hotend with minimal distance, providing precise control over filament retraction and extrusion.

- Bowden Extruders: Bowden extruders, on the other hand, have the motor mounted on the frame of the printer, feeding the filament through a long Bowden tube to the hotend. This setup reduces the moving weight of the print head, but the increased distance can affect the precision of filament control.

2. Effects on Print Speed

- Direct Drive: Typically better for slower, high-quality prints. The extra weight on the print head can limit how fast you can print without sacrificing print quality due to inertia and vibration. However, with new technology continuing to develop, direct drive printers are proven to be just as fast as bowden printers with the right parts. Extruders like the Mini Sherpa or LDO Orbiter are great examples of direct drive extruders with minimal weight, maximum power, and high efficiency.

- Bowden: Can allow for higher print speeds since the print head is lighter and can move more quickly without introducing wobble. This makes bowden extruders better in regards to print speed depending on the set up of your printer and your level of knowledge in 3D printing.

3. Materials You Can Print

- Direct Drive: Excels with flexible and exotic filaments like TPU, TPE, and other soft materials due to its precise filament control and reduced retraction distance.

- Bowden: Struggles with flexible filaments as the long tube can cause the filament to buckle or tangle. It’s best suited for more rigid materials like PLA, ABS, and PETG.

4. Cost and Maintenance

- Direct Drive: Can be more expensive due to the complexity of mounting the extruder motor on the print head. However, most all extruders can be mounted using 3D printed mounts. These mounts are easy to print and only cost a few cents.

- Bowden: Typically more affordable and easier to maintain because the extruder motor is separate from the print head, reducing stress on the print head assembly.

Which One is Right for You?

- Choose Direct Drive if: You prioritize printing with flexible or specialty materials.

- Choose Bowden if: You mainly use rigid filaments. It’s a cost-effective choice for those who prioritize speed and are willing to stick to standard materials.

Each extruder type has its place in 3D printing, and the right choice ultimately depends on your specific needs and the kinds of projects you plan to tackle.